These covers assist to reduce the splatters a result of the milling functions. Furthermore, it safeguards the machinists and also the atmosphere from your machining Procedure.

If we speak about vertical machining centers They can be considerably far more precise and correct than horizontal machining centers which is among its constructive facets in comparison to horizontal machining centers.

Stay clear of acquiring overly intricate CNC machine tools with too many functions that aren't useful, even should they come in a higher Value.

CNC machine tools have intricate and comprehensive characteristics, leading to several components that could potentially cause faults. Thus, various fault analysis approaches may have for use alongside one another to comprehensively assess the fault and quickly determine its place, facilitating its resolution.

To make a complicated three-dimensional component, lots of machines require a 4th or simply 5th axis to complete these kinds of an item. Perfect for cutting plastics and aluminum, this machine remains to be rigid enough to cut more difficult supplies like brass and titanium.

Electrical Discharge Machines (EDM) employ electrical sparks that erode the fabric in a very pre-determined route. A wire or electrode Within the dielectric Along with the workpiece generates the spark as high voltage passes by way of it.

Photon Automation (in Greenfield, IN) producers tailor made, produced-to-get parts. The business has five Hurco CNC machines, which includes a VMX42i 3-axis mill. Along with the precision and rigidity from the VMX, CEO William Huffman explains the intuitive character from the Hurco conversational control can make it uncomplicated to seek out machinists given that they don’t require to be aware of G-code to run the machines. Just click here to watch much more client testimonial video clips.

The second essential component should be to master the guide or automated operation in the CNC machine Microcut machining system Device plus the movement of each and every CNC axis.

If an oscilloscope or recorder just isn't available on-internet site, In keeping with knowledge, adjust the parameters until finally the motor vibrates, after which you can slowly but surely regulate in the opposite course right until the vibration is eliminated.

The geometry of a Resource frequently influences the cutting specifications and success. The horizontal machining centers are shorter and thicker, which implies they may have The steadiness necessary to sustain resistance though machining deeper cuts.

The CNC system’s ability to promptly method info allows multi-channel and swift sign acquisition and processing with the faulty element. The diagnostic system then performs a logic analysis and judgment to determine when there is a fault inside the system and promptly Track down it.

The spindle axis on the vertical machining center is about perpendicular on the workbench and is especially ideal for processing elaborate elements including plates, discs, molds, and smaller shells.

Additionally, our engineers and operators have about 20 years of knowledge in machining jobs. In the event you are interested, add your style right here and request a estimate. All uploads and knowledge are highly confidential!

The main stage of fault detection involves testing the CNC machine Device to ascertain if a fault exists.

Joseph Mazzello Then & Now!

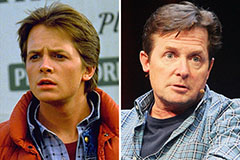

Joseph Mazzello Then & Now! Michael J. Fox Then & Now!

Michael J. Fox Then & Now! Kenan Thompson Then & Now!

Kenan Thompson Then & Now! Seth Green Then & Now!

Seth Green Then & Now! Dolly Parton Then & Now!

Dolly Parton Then & Now!